We have over 20 professional smd led engineers, independent LED encapsulation lab,can achieve high and low temperature cold and hot shock test, anti-vulcanization test,moistureproof test,constant temperature and humidity test,LM-80 Standard 6000H continuous light attenuation test,etc.Products have more than 30 patents.

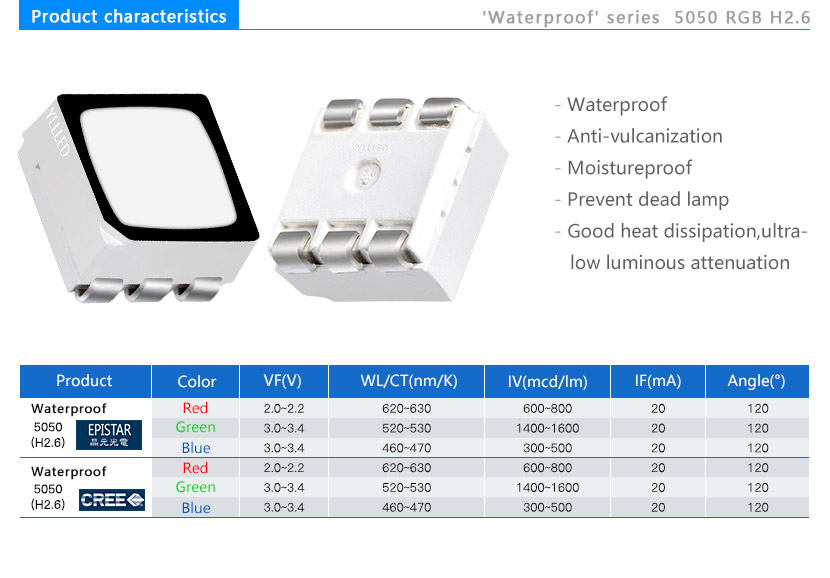

10 years LED encapsulation experience,over 6000m? modern dust-free workshop,firstly bring out "three proofings" technology which can perfectly resolve the problems:high dead lamp rate,vulcanization, moisture absorption,etc,truly realize moistureproof, anti-vulcanization,prevent dead lamp.

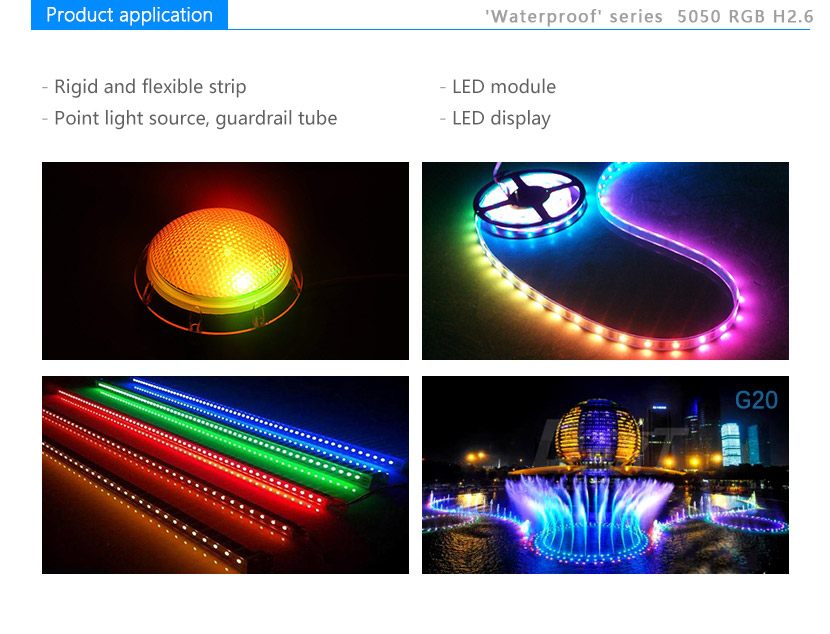

We firstly apply "waterproof technology" to realize waterproof of 3528 lens(50-60°),5050RGB,3535RGB, 3535 white light.

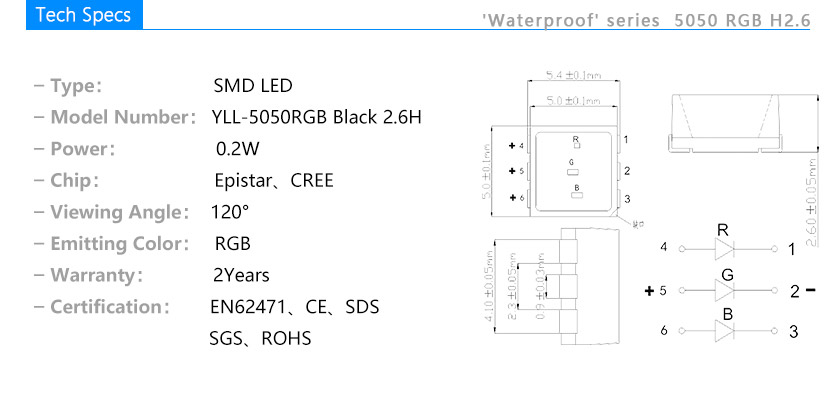

Chips mainly from international manufacturers(EPISTAR,CREE,OSRAM), we strengthen integration of supply chain resources to do IQC, process specification, improve OQC process, and strive to make satisfying products.

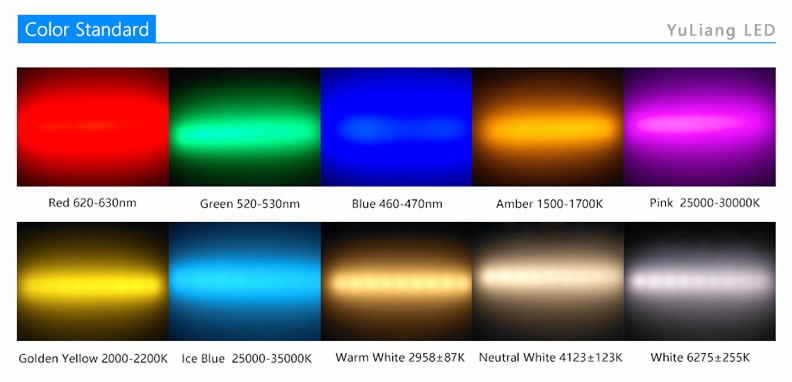

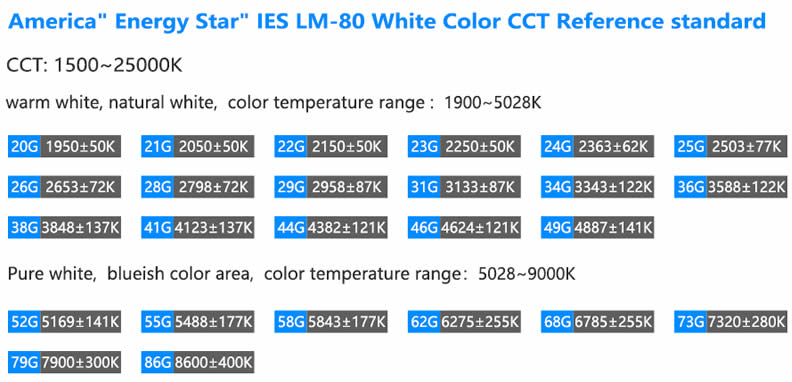

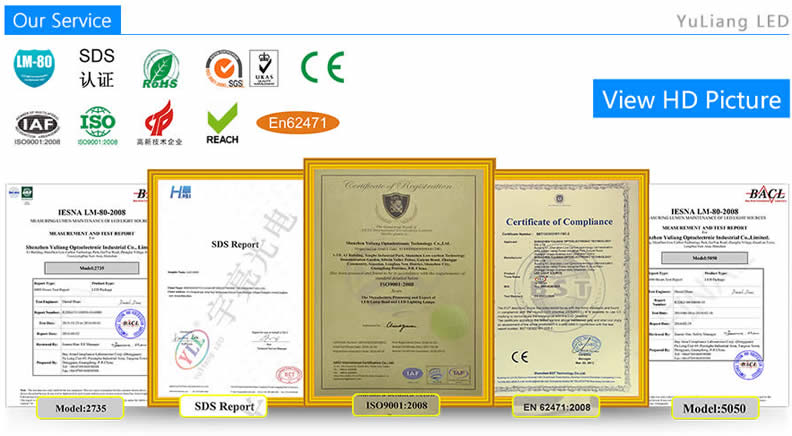

We operate strictly in accordance with ISO9001:2008 quality management system,white light color area strictly complies with American Energy Star IES LM-80 standard.A number of products have passed the certification of Energy Star IES LM-80, SGS, RoHS, EN62471, etc.

We promise our customers to long-term supply 1 BIN for regular color temperature products,sample making within 3 days as customer's requirement, small batch orders completed within 5-7 days, conventional products completed within 1-2 days, customer complaints within 24 hours response, timely and efficiently deal with a series of problems customers faced with.